Description

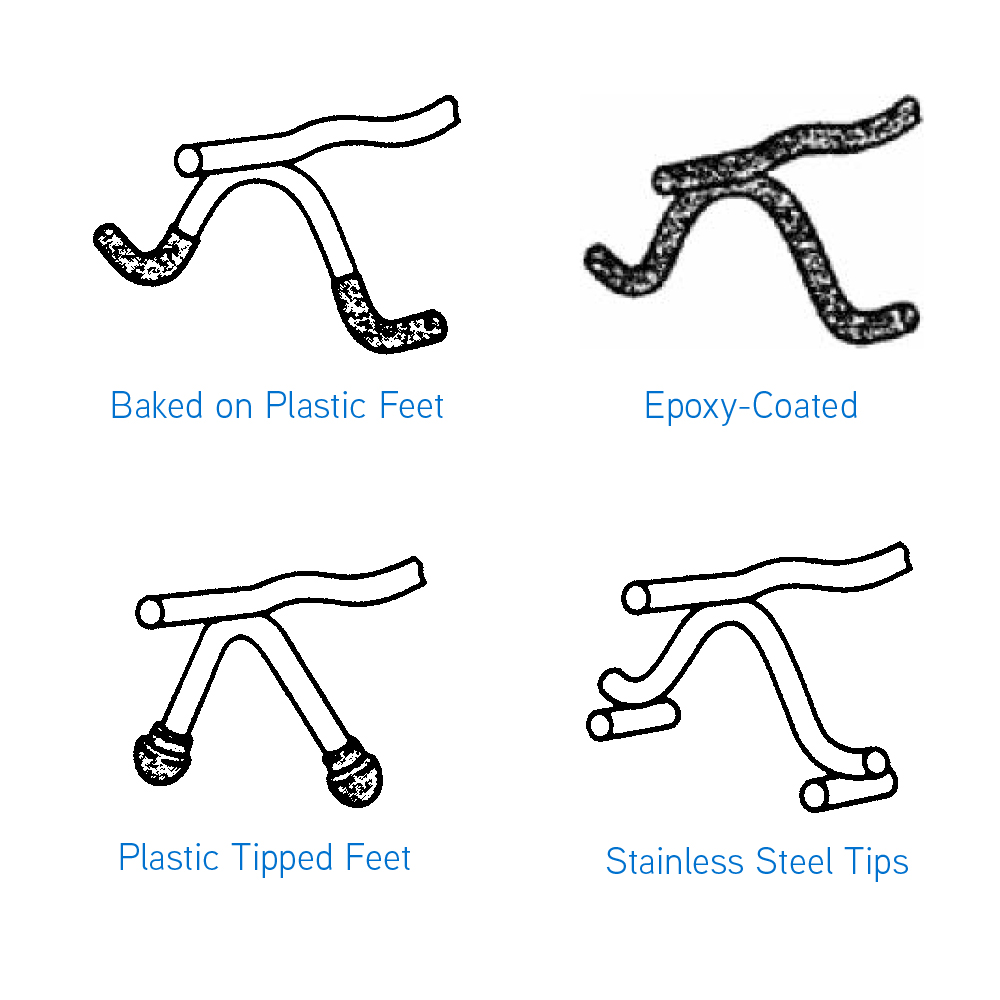

Rust Prevention

Bar supports are classified in terms of methods employed to minimize rust spots or similar blemishes on the surface of the concrete directly caused by the bar support. The three classes and their intended degree of protection are:

Class 1

Plastic or Plastic Protected

(FORMERLY CLASS C)

Maximum protection; which is intended for use in situations of

moderate to severe exposure and/or situations requiring light

grinding (under 1/16″) or sandblasting of the concrete surface.

Class 1A

Maximum Protection

(FOR USE WITH EPOXY-COATED REINFORCING BARS) Epoxy-Coated, Vinyl-Coated, or Plastic-Coated Bright Basic Wire Supports — which are intended for use in situations of moderate to maximum exposure where no grinding or

sandblasting of the concrete surface is required. They are generally used when epoxy-coated reinforcing bars are required.

Class 2 Type A

Stainless Steel Protected

(FORMERLY CLASS D)

Moderate protection; which is intended for use in situations of moderate exposure and/or situation requiring light grinding (under 1/16″) or sandblasting of the concrete surface.

No non-stainless steel wire of the bar support will be closer than 1/4″ from the form surface. Aluminum oxide wheels should be used when grinding is necessary. Iron oxide will leave rust marks.

Class 2 Type B

Stainless Steel Protected

(FORMERLY CLASS E)

Moderate protection; which is intended for use in situations of moderate exposure and/or situation requiring light grinding (under 1/16″) or sandblasting of the concrete surface.

No non-stainless steel wire of the bar support will be closer than 3/4″ from the form surface. Aluminum oxide wheels should be used when grinding is necessary, Iron oxide will leave rust marks.

Class 3

No Protection

(FORMERLY CLASS A)

No protection against rusting; which is intended for use in situations where surface blemishes can be tolerated, or where the supports do not come in contact with the exposed concrete surface.