Description

TECHNICAL DATA

| Chemistry | Silyl-Terminated Polyether – Moisture Cure | |

| Density | 12.2 +/- 0.2 lb./Gal. (12.2 +/- 1.46 kg/L) |

ASTM D1475 |

| Viscosity at time of manufacture | 900,000 +/- 200,000 cps | 70° F (21.1° C) +/- 2° F (-16.7° C) Brookfield RVF, TC Spindle, 4 RPM |

| Tack-Free Time | 30 min +/- 15 min | ASTM C679 |

| Shear Strength | 210 psi +/- 25 psi | ASTM D412 |

| Tensile Strength | 230 psi +/- 25 psi | ASTM D412 |

| Elongation at Break | 215% +/- 25% | ASTM D412 |

| Low Temperature Flex | Pass @ -10° F (-23° C) | ASTM D816 |

| Shore A Hardness | 38 +/- 5 | ASTM C661 |

| Installation Temperature | >32° F (0° C) | |

| Service Temperature | -20° F to 200° F (-29° C to 93° C) |

|

| Shrinkage | No Visible Shrinkage After 14 Days | |

| Exposure Time | 12 Months | |

| VOC Content | 19 g/L | |

| Color | Green | |

APPLICATION

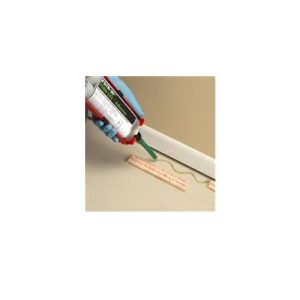

Surface Preparation … All surfaces to receive AIR-SHIELD LIQUID FLASHING should be clean, smooth, and free from all bond-breaking contaminants. Product can be applied to damp surfaces if it is clean. Remove any damaged structural wall components. Any raw edges of exterior gypsum board may require adhesive. For detailed instructions, view our AIR-SHIELD LIQUID FLASHING INSTALLATION GUIDELINES document.

Application Method

Rough Opening … Inspect rough opening. The rough or cut edge of gypsum board should be applied with adhesive. Prefill any gaps larger than ¼” (6.35 mm) with AIR-SHIELD LIQUID FLASHING and allow to skin over.

Apply bead of AIR-SHIELD LIQUID FLASHING in opening to be sealed. Spread the material using putty knife across rough opening surface. Next, apply a thick bead of material to the structural wall surface around rough opening. Again, spread the material evenly using a putty knife. Make sure material is spread in an even, monolithic manner. Make sure to spread the material 12 – 15 mils [4″ – 6″ (100 – 152 mm)] on to structural wall. Make sure material contains no pinholes and is void-free. Again, make sure material is even, monolithic, and undamaged.

Make sure AIR-SHIELD LIQUID FLASHING covers the entire opening and seamlessly joins the specific AIR-SHIELD membrane being installed. Allow surface to dry before installing windows, doors, wall assembly, and specific AIR-SHIELD membrane being applied.

AIR-SHIELD LIQUID FLASHING is also compatible with the entire line of AIR-SHIELD products for joint detailing in exterior sheathing panels. For detailed application instructions, please view our AIR-SHIELD EXTERIOR SHEATHING PANELS INSTALLATION GUIDELINES document.

Drying Time … At 70° F (21° C) and 50% relative humidity, product skins within 30 minutes. AIR-SHIELD LIQUID FLASHING is moisture curing. Low temperatures and low relative humidity slow dry time. High temperatures and high relative humidity accelerates dry time.

PRECAUTIONS

Not for use as a structural sealant. Not for use in place of AIR-SHIELD THRU-WALL FLASHING. Not for use below-grade or in locations designed to be continuously immersed in water. When painting, use latex paints only.

LEED INFORMATION

May help contribute to LEED credits:

- EA Credit 1: Optimize Energy Performance

- IEQ Credit 3.1: Construction Indoor Air Quality Management Plan: During Construction

- IEQ Credit 4.2: Low-Emitting Materials – Paints and Coatings

- IEQ Credit 7.1: Thermal Comfort – Design

- MR Credit 2: Construction Waste Management

- MR Credit 5: Regional Materials

This material last updated January 2015.