AIR-SHIELD THRU-WALL FLASHING – Membrane Flashing

AIR-SHIELD™ THRU-WALL FLASHING

Flexible Flashing

AIR-SHIELD THRU-WALL FLASHING is a self-adhering, flexible membrane flashing.

DESCRIPTION

AIR-SHIELD THRU-WALL FLASHING is a self-adhering, flexible membrane flashing. It is a roll-type product that is nominally 40 mils thick. This material is an air, vapor, and liquid moisture barrier.

USES

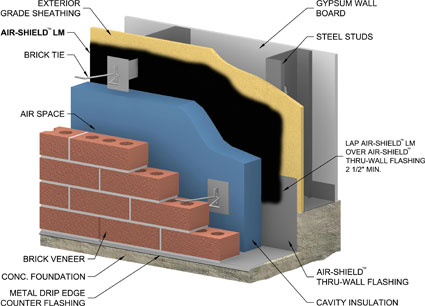

AIR-SHIELD THRU-WALL FLASHING is a concealed flashing for masonry concrete, wood/steel frames, and roofing applications – door and window lintels, sills, spandrel beams, caps, and parapets. AIR-SHIELD THRU-WALL FLASHING is designed for use as a thru-wall flashing and dampproofing course.

FEATURES/BENEFITS

- Controlled thickness membrane is ideal for flashing membrane applications.

- Cross-laminated polyethylene film has excellent tensile strength, elongation, and tear-resistance.

- Modified membrane is flexible at low temperatures.

- Rugged membrane can actually fold to shape during application as a thru-wall flashing.

- Excellent adhesion to prepared substrates of precast concrete, cast-in-place concrete, masonry (concrete block), interior and exterior gypsum board, Styrofoam, primed steel, aluminum mill finish, anodized aluminum, primed galvanized metal, drywall, and plywood.

- Self-healing characteristics facilitate recovery if minimal damage is sustained under normal use applications.

- No flame required.

- Low temperature version also available.

PACKAGING

Roll Sizes Available in cut sizes

Also available in cut rolls of 4″, 6″, 9″, 12″, 16″, 18″, 20″, and 24″ (102, 152, 224, 326, 406.4, 457.2, 508, and 609.6 mm) wide. NOTE: Some sizes require lead time. All rolls are 75′ (22.9 m) long.

TECHNICAL DATA

Thickness 40 mils (nominal)

APPLICATION

Surface Preparation … All surfaces to receive AIR-SHIELD THRU-WALL FLASHING should be clean, dry, smooth, and free from projections that could puncture the membrane. Prepare substrate per manufacturer’s instruction prior to application of membrane. Surfaces shall be free of scale, rust, grease, and oil and conditioned with MEL-PRIME™, MEL-PRIME N.E. or MEL-PRIME W/B from W. R. MEADOWS.

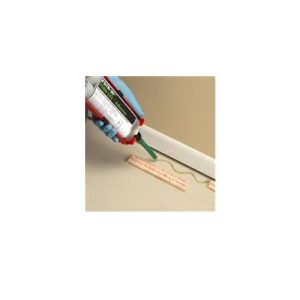

Application Method … Remove release paper prior to application. AIR-SHIELD THRU-WALL FLASHING should be recessed a minimum of 1/2″ (13 mm) from the face of the masonry. Flashing should not be permanently exposed to sunlight. Do not allow the rubberized asphalt surface of the flashing membrane to contact sealants containing solvents, creosote, uncured coal tar products, EPDM, or PVC components. If AIR-SHIELD THRU-WALL FLASHING is not embedded in the masonry joint, apply TERMINATION BAR from W. R. MEADOWS at the top edge (and seal with POINTING MASTIC from W. R. MEADOWS) to mechanically fasten the flashing membrane. Overlaps of the flashing should be a minimum of 4″ (102 mm). Where flashing sections overlap, the seam created by the overlap should be sealed with POINTING MASTIC.

Open Cavity Installation … AIR-SHIELD THRU-WALL FLASHING should always be supported across the full width of the wall cavity below. Proper design should provide support with a cavity bridge to ensure AIR-SHIELD THRU-WALL FLASHING does not sag in the open cavity and collect water.

Make sure to follow all Masonry Institute of America applications and precautions.

PRECAUTIONS

Intended for concealed and protected applications; not intended for uses subject to abuse or permanent exposure to the elements.

LEED INFORMATION

May help contribute to LEED credits:

- EA Credit 1: Optimize Energy Performance

- IEQ Credit 3.1: Construction Indoor Air Quality Management Plan: During Construction

- IEQ Credit 7.1: Thermal Comfort – Design

- MR Credit 2: Construction Waste Management

- MR Credit 5: Regional Materials

This material last updated September 2015.