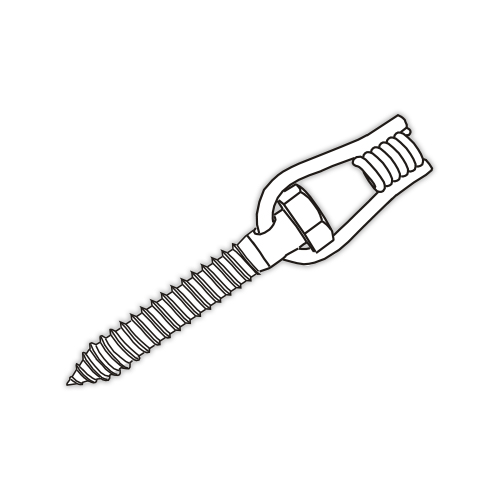

Steel Dog SCL coil lag

For securing formwork to timber structures

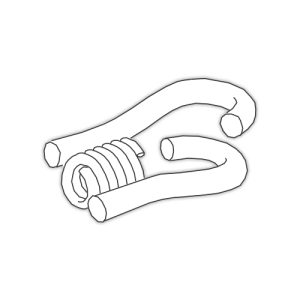

- 3/4″ hex head lag bolt with swiveling loop coil tie

- Available for 1/2″ coil rod or 1/2″-13NC machine thread

- Useful for one-sided walls against wood lagging

- 3000 lbs Max. Safe Working Load (see load tables)

The Steel Dog® Coil-Lag™ is designed to provide a temporary means of attaching formwork to wood timbers. Typical application: one-sided forming against soldier piles with wood lagging, or other timber retaining walls.

Features

- Standard hex head lag bolt for socket wrench or powered driver installation.

- Swivel loop coil tie end to accommodate misalignment between lag bolt placement and formwork tie location.

- Accepts standard ½”coil rod or ½”-13 NC rod (SCL-4NC)

- Less expensive than toggle ties, and doesn’t require clear space behind timber (compacted fill not a problem).

- Eliminates expensive external bracing or welding.

Material

Bolt is ASTM A307. Swivel loop wire is AISI C1038.

FINISH None. Zinc coatings available: consult factory.

MAXIMUM SAFE WORKING LOAD 3000 Lbs. (2-to-1 safety factor). Actual Safe Working Load will depend on pull-out strength of lag in wood and off-axis loading angle. See tables at right.

Download Coil Lag Spec Sheet