Description

TECHNICAL DATA

| Property | Test Method | PRECON Results |

| Color | Black | |

| Thickness | ASTM D 1000 | 73 mil (1.85 mm) |

| Low Temp Flexibility | ASTM D 1970, 180° @ -25° F (-32° C) | Pass |

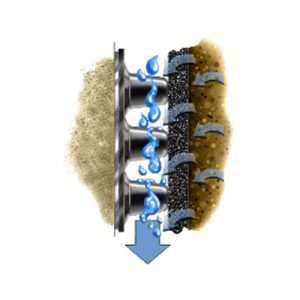

| Resistance to Hydrostatic Head | ASTM D 5385-93 | 230′ (70 m) |

| Elongation, Polymeric Membrane | ASTM D 412-06 | > 400% |

| Tensile Strength, Film | ASTM D 882 | 9200 psi (63.4 MPa) |

| Crack Cycling | ASTM C 836 @ -15° F (-26° C) | Pass |

| Puncture Resistance | ASTM E 154 | > 210 lb. (> 934 N) |

| Peel Adhesion to Concrete | ASTM D 903 | 10 lb./in (1754 N/m) |

| Moisture Vapor Transmission | ASTM E 96B | 0.0011 perms (0.0004 grains/ft.2/hr) (0.007 gram/m2/24 hr) |

| Resistance to Penetration by Termites |

Texas A&M Method Percentage of Penetration |

0.0% |

| Resistance to Penetration by Pesticides |

ASTM F 2130 Percentage of Penetration |

0.0% |

| Resistance to Fungi in Soil | GSA-PBS 07115 – 16 Weeks | No Effect |

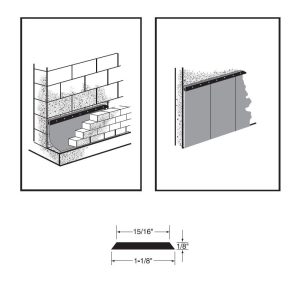

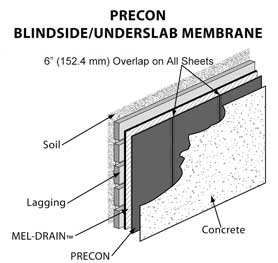

In vertical applications of PRECON, mechanically attach with fasteners every 12″ (31 cm) across the top, within ½” (13 mm) of the top edge of the membrane. Install the membrane with the fabric side facing toward the concrete pour.

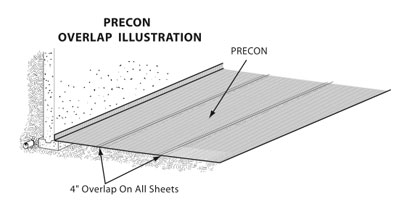

Remove release paper on 6″ (152.4 mm) overlap. Apply membrane and roll press into place with a tile type roller.

End Laps … Overlap membrane 6″ (152.4 mm). Prior to overlap, apply BEM, HYDRALASTIC 836 or *MEL-ROL® LIQUID MEMBRANE (two-component) from W. R. MEADOWS in area to be lapped. Roll press membrane into BEM, HYDRALASTIC 836 or MEL-ROL LIQUID MEMBRANE. At terminations of membrane, apply BEM, HYDRALASTIC 836 or MEL-ROL LIQUID MEMBRANE 12″ (31 cm) wide centered over the termination and while still wet, embed 12″ (31 cm) wide DETAIL FABRIC into the HYDRALASTIC 836 or MEL-ROL LIQUID MEMBRANE and roll press into place. Ensure that DETAIL FABRIC is centered over the termination with 6″ (15.2 cm) on each side of lap edge. Apply additional HYDRALASTIC 836 on all terminations of DETAIL FABRIC.

Penetrations and Protrusions … Detail around all horizontal and vertical penetrations using BEM or MEL-ROL LIQUID MEMBRANE (two-component) from W. R. MEADOWS. Apply BEM or MEL-ROL LIQUID MEMBRANE by forming a fillet around the pipe or protrusion, overlapping the fabric side of PRECON and the protrusion a minimum of 2.5″ (64 mm). If the gap between the protrusion and the membrane is greater than ½” (13 mm), apply PRECON FABRIC TAPE over uncured BEM or MEL-ROL LIQUID MEMBRANE. All penetration and protrusion surfaces must be clean, rust-free, and sound prior to application of BEM or MEL-ROL LIQUID MEMBRANE.

*MEL-ROL LIQUID MEMBRANE is a two-component material, not to be confused with MEL-ROL LM.

Patching … Prior to pouring, inspect membrane for punctures or damage and repair as necessary with HYDRALASTIC 836 and/or DETAIL FABRIC. (BEM or MEL-ROL LIQUID MEMBRANE may be used in place of HYDRALASTIC 836.) In addition, ensure the membrane is free of standing water and has been cleaned of any deleterious materials that will affect the bond of the concrete to the membrane.

Underslab Application … Refer to ACI 302.1R-04: Chapter 4 – Site Preparation and Placing Environment for sub-grade preparation prior to PRECON placement.

PRECAUTIONS

Concrete should be poured within 60 days of membrane installation. For installations below 40° F (4° C), contact W. R. MEADOWS technical services. When using bar supports, use those with a flat bottom.

LEED INFORMATION

May help contribute to LEED credits:

- EA Credit 1: Optimize Energy Performance

- IEQ Credit 3.1: Construction Indoor Air Quality Management Plan: During Construction

- IEQ Credit 7.1: Thermal Comfort – Design

- MR Credit 2: Construction Waste Management

- MR Credit 5: Regional Materials

FEATURES/BENEFITS

FEATURES/BENEFITS